![]()

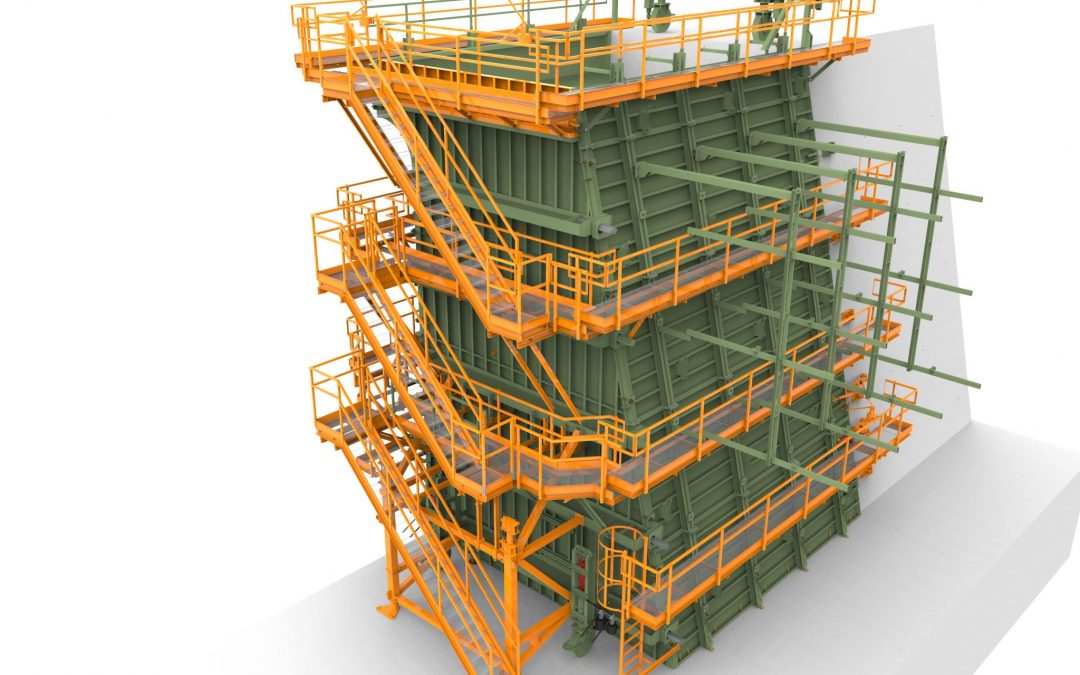

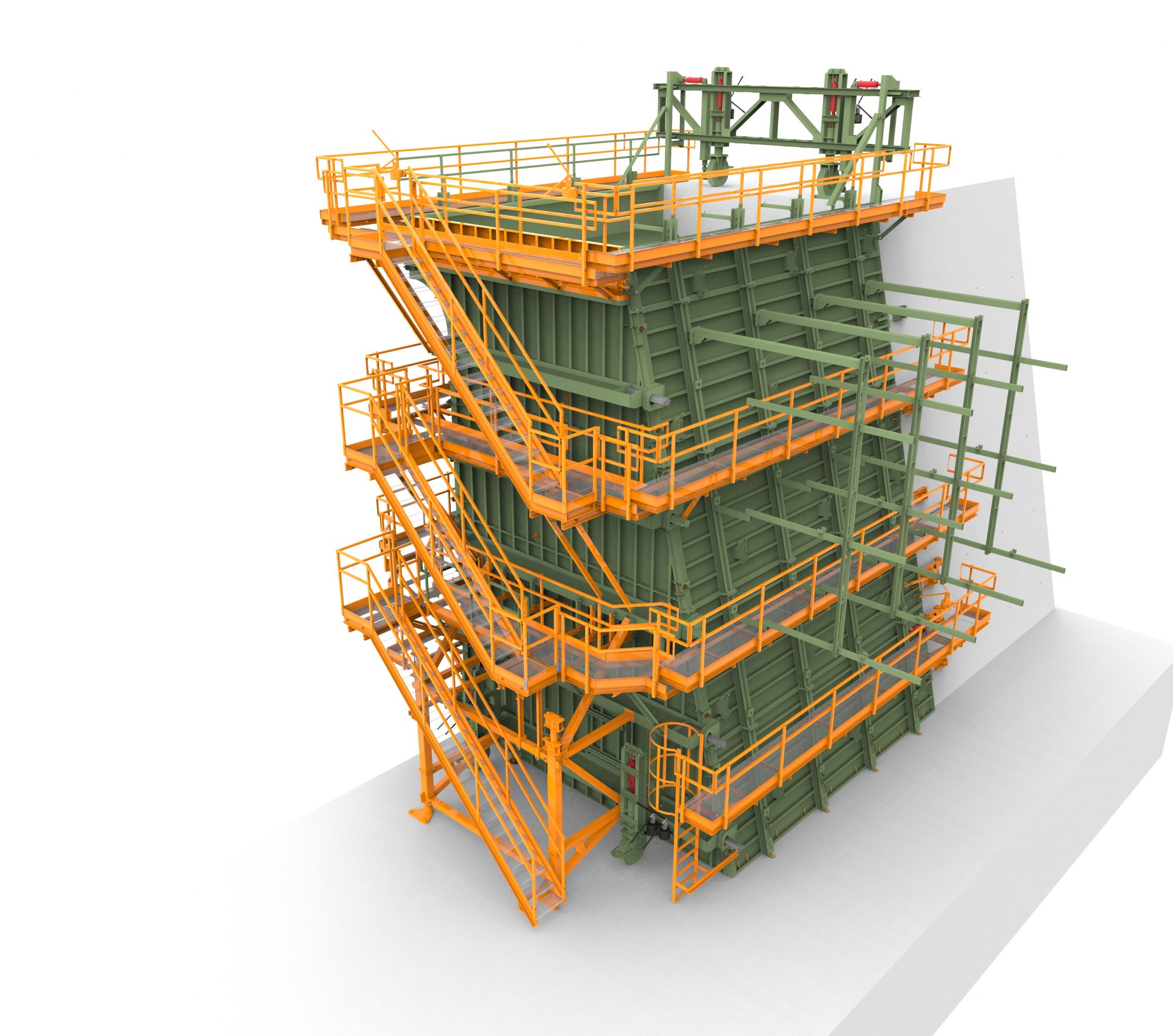

Crown Wall formwork equipment

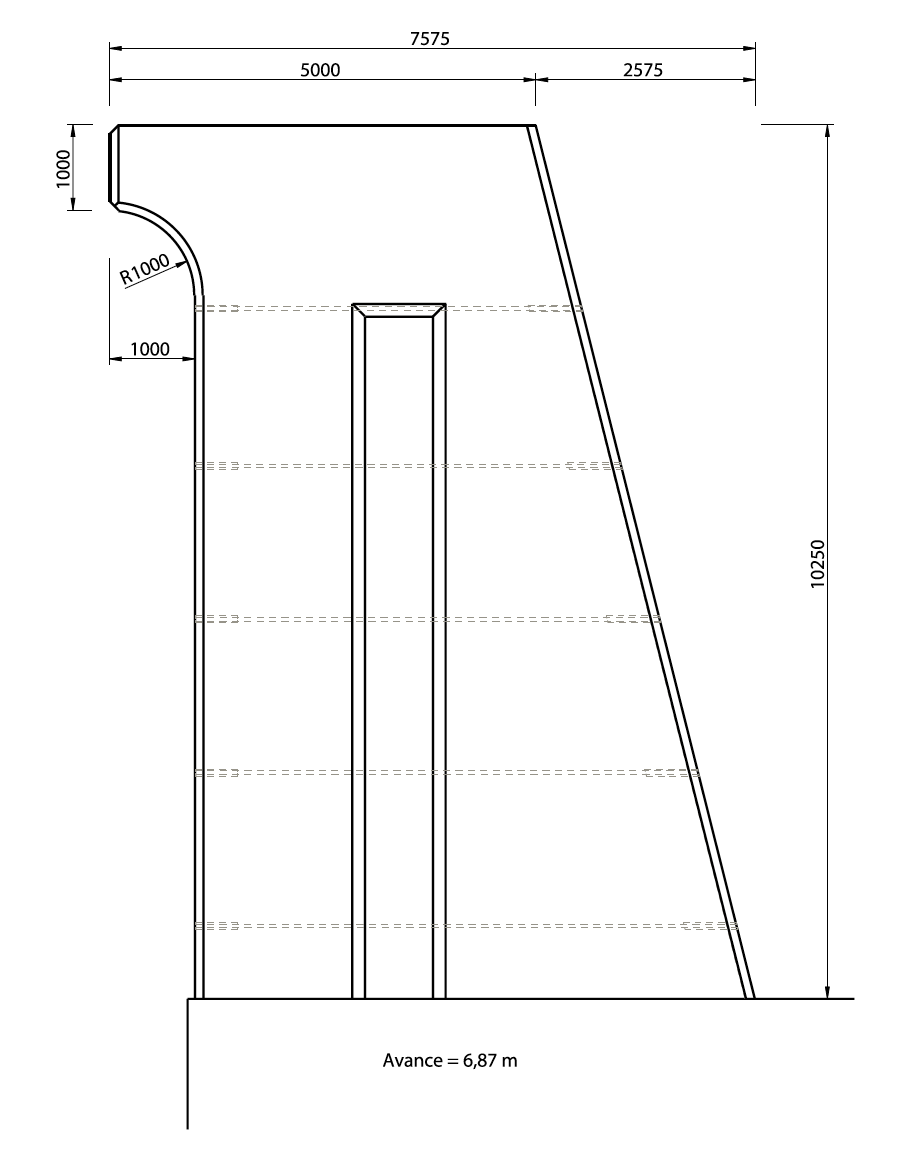

The side panels are slightly longer than the length of the formwork advance to allow an overlap with the previous phase, in order to achieve proper alignment and at the same time prevent any slurry leakage.

Both side panels are fastened together by DYWIDAG bars through the concrete and are connected by a crossbeam assembly on the upper section. On the front section they are secured to the end panel whilst on the rear section they are secured to the rear crossbeam. The end panel and the rear crossbeam house wheels which enable the formwork to advance and for the side panels’ opening-closing systems. In addition, the formwork is equipped with working platforms to enable access to all the elements which must be handled. For formwork of considerable size, hydraulic cylinders open and close the side panels, whilst for smaller formwork this is via manual ball screws.

To prevent forward movement of the mould during concreting, a series of fixings to the section already in place takes advantage of the tie bar holes left in the previous block. During concreting, formwork is held in place by ball screws, usually in the end panel and rear beam. The form traveller is transferred to a new concreting position by movable wheels, for steering during the transfer. Formwork is launched over the work.