![]()

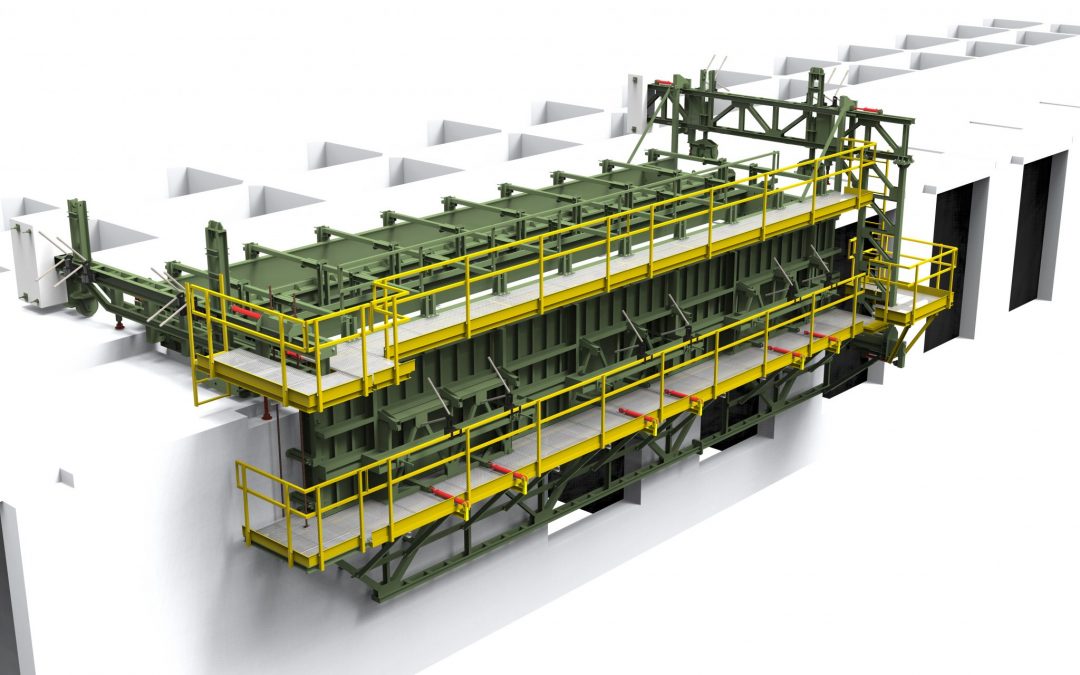

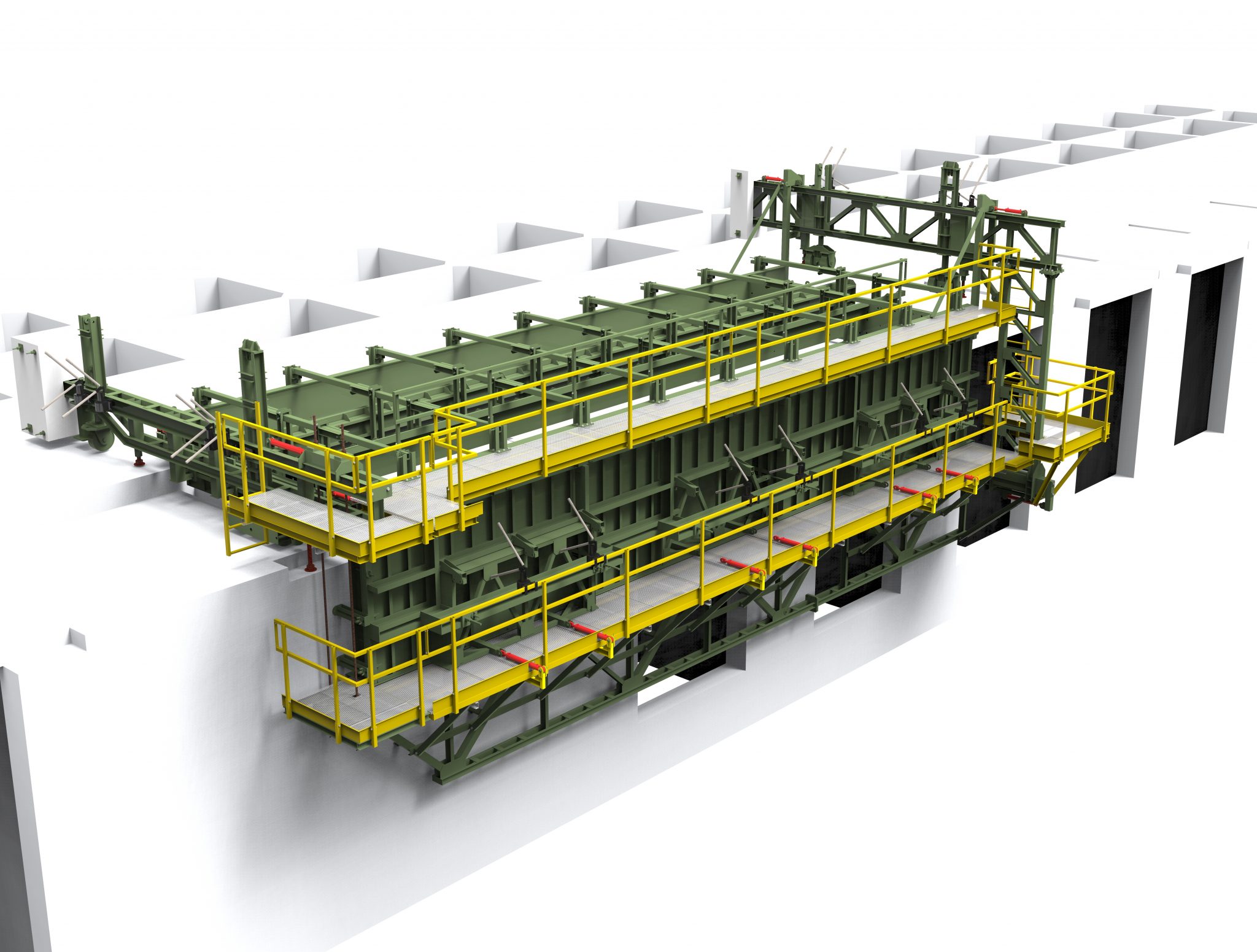

Capping Beams formwork equipment

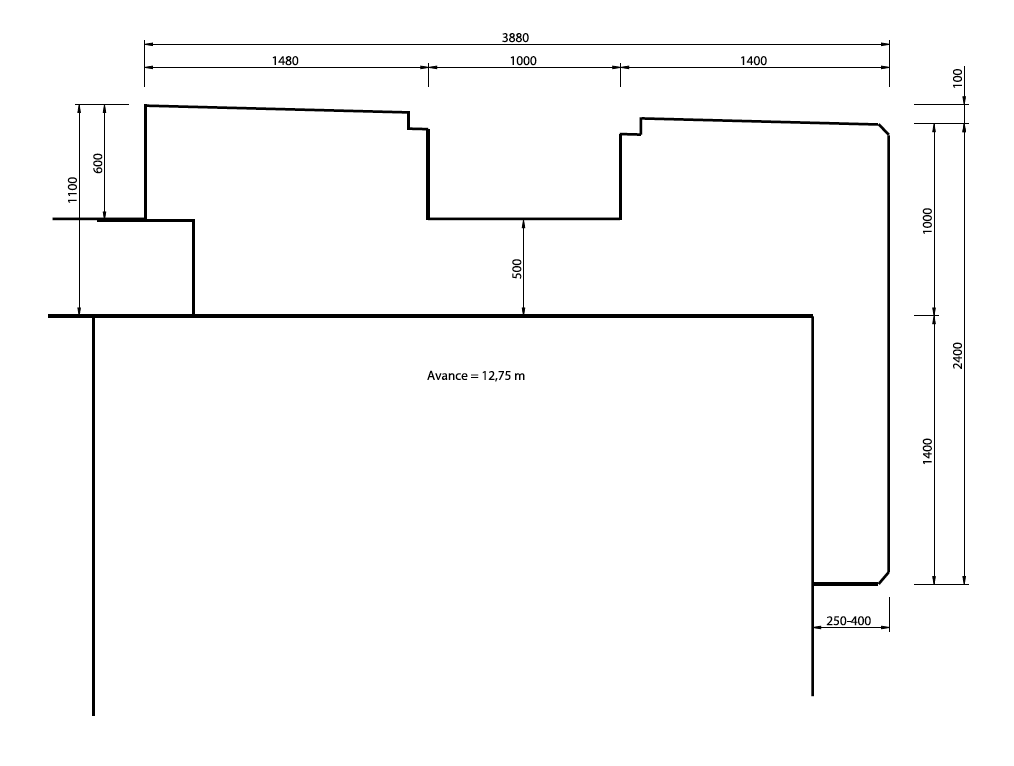

The side panels are slightly longer than the formwork advance length in order to allow an overlap on the rear with the previously concreted section, thereby facilitating proper alignment between sections, and at the same time preventing slurry leaks.

The seaward panel enables sections to be constructed with a special length apron for the sea defence area and anchoring components can be left in position for sea defences.

Seaward and landward panels are secured together by tie bars, and via cross beams on the upper section. In addition, they are secured to the end panel on the front section and secure the rear section of the rear beam. Opening and closing the panels and lifting and lowering the mould for the advance, is via hydraulic cylinders located on the rear beam and end panel. The form traveller advance is on suitably sized wheels, positioning the front section on a suitable bed and the rear section directly on the completed previous phase.

To prevent the structure tipping over during the concreting process ballast is required to be provided on site with RUBRICA supplying plans and dimensions, plus details of its positioning in the installation. To prevent forward movement of the mould during concreting, a series of fixings to the section already in place takes advantage of the tie bar holes on the previous block. The structure is equipped with platforms in order that the workforce can access the various working areas of the mould.